the@vanced Connectivity in a nutshell

the@vanced Connectivity lets your Kampf machine be integrated with external software systems (ERP / MES). By interfacing with third-party systems, you take the automation of your equipment to the next level.

| Integration into MES / ERP-Systems | |

| Real-time data transfer | |

| Preparation for Digital Product Passports |

The integrative module

the@vanced

Connectivity in detail

the@vanced

Connectivity in detail

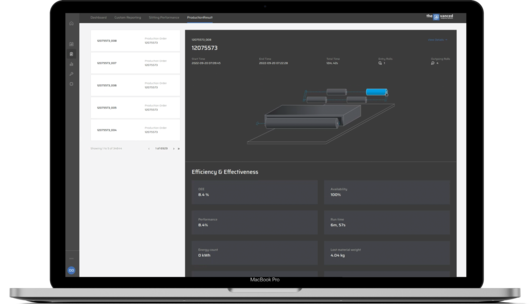

The Connectivity package adds standardized interfaces for external software systems to the functions already integrated in the machines. These interfaces enable you to transfer order data directly from MES or ERP systems (Manufacturing Execution System, Enterprise Resource Planning) by other suppliers to your Kampf machine and to report production results back to existing systems.

Automation saves you time and avoids errors. In addition, you can further optimize your production by analyzing live machine data.

Ready for a sustainable future.

Thanks to its interfaces, Connectivity readies the@vanced platform for the exchange of data with other higher-level systems. For example, the@vanced Essential package facilitates the implementation of the R-Cycle solution for tracking plastics throughout their lifecycle. Compatibility with other systems will be continuously extended via future updates.

More from the@vanced

Essential

| The basic package — your point of entry into the world of digital solutions. Minimize downtimes with access to remote services and direct contact to experienced service specialists. | |||

| Access to remote services | Machine record | |||

| Comprehensive online analysis | State-of-the-art security | |||

| Future-proof through digital R-Cycle product passport preparation | Live status of all connected machines | |||

| Direct line to service | ||||

Assistance

The flat rate that complements Essential: Permanent remote service that secures your cost advantage.

| Remote services flat rate | |

| Ideal addition to Essential | |

| Scalable for all machines | |

| Cost-saving graduated pricing model |